We are talking about airplanes here and not cruise ships

hitting Icebergs. However, it’s so important

to be World’s Biggest at something. May as well be at airplane making and

Boeing remains the World’s Biggest deliverer of airplanes. Which is good only

if enough backlog exists for that YOY status report. Airbus once was World’s

Biggest until Boeing built more production and infused the 787 line found in

two cities while taking a page out of the Airbus play book.

So Orders do eventually matter over time and Airbus has so

many it can’t build airplanes fast enough or can it deliver to not so happy customers

in waiting. Boeing says production is the key to its nirvana in Seattle. Airbus

says we have more orders than Boeing every day somebody is listening. I hope no one wants an airplane

soon from Airbus. This chapter could go on forever as Airbus is building about

90 WB‘s a year and Boeing is building about 175 WB’s a year when including 767,

787,777 and 747 types. Airbus has its A330, A350 and A380 lines churning as

fast as it can.

The most important note, if taking notes is that a delivery =

CASH! Orders equals bragging rights. Boeing beats Airbus with its cash account

and Airbus just brags a lot even after Airbus John Leahy retires.

The main thing for Airbus is that if it can’t deliver in a timely manner it will lose orders and customers. Those are called cancellations. This is a big Airbus metric to watch.

The main thing for Airbus is that if it can’t deliver in a timely manner it will lose orders and customers. Those are called cancellations. This is a big Airbus metric to watch.

Boeing is a producer and that makes airline customers happy.

A customer can get a timely delivery from Boeing and a customer can delay a delivery

when it wants to as Boeing has a fairly stable backlog (unfilled orders). The definition of

backlog is unfilled orders from customers who happen to have ordered. Airbus has an immense

single aisle backlog greater than Boeing’s single aisle backlog. Airbus needs

to build single aisle with more production, and it must keep suppliers happy

too by not overburdening the parts supplier into oblivion.

Airbus tried a new tack, duo engine offering for its A320. All went well when one engine maker stumbled. The P&W gear driven jet engine has teething woes much like what the 787 went through when exposing its own all new technology after the first 787 delivery. The P&W engine is often parked on a factory bench for further inspection and repair.

Airbus tried a new tack, duo engine offering for its A320. All went well when one engine maker stumbled. The P&W gear driven jet engine has teething woes much like what the 787 went through when exposing its own all new technology after the first 787 delivery. The P&W engine is often parked on a factory bench for further inspection and repair.

Airbus is having supply chain issues and engine issues when

it should be delivering 70 single aisle A320’s a month. Instead, it is shooting

for 60 A320’s a month. It only delivers about 5-7 A350’s a month. Boeing

delivers about 12, 787 a month. It also delivers copious amounts of 777-ERs which

is a very big dual aisle aircraft. In fact it is running out of 777’s work

orders as a diminishing 777-300ER backlog is a backdrop to the 777X program.

Boeing should be fine if it executes the 777X program well after the 777X first

delivery.

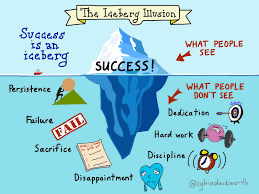

The main thing both manufacturers face, are the business

Icebergs creeping up on its supply chains, engine makers, and fickle customers.

If either airplane maker strikes one of those Icebergs it will be hard to

deliver its customer a value, I only mean the commercial airline (customer). The

commercial carrier so desperately needs to deliver value to its own customers, you them as passengers and so forth…

No comments:

Post a Comment